|  | |||

|  | |||

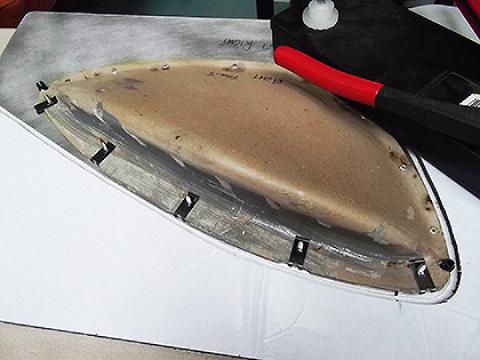

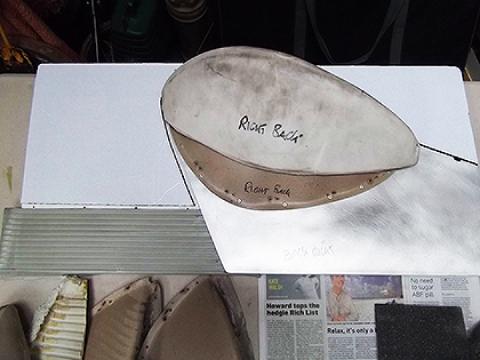

I decided to undertake the last major trimming job largely by myself - making the new door cards. It took a long time to find a full set of arm rest padding which was in good enough condition. Nearly all arm rests which have been cloth covered are useless (hard and crusty). Leather covered Pallas items are sometimes OK (better protected), but they are a different size (longer). Those from vinyl trimmed IDs or DS Specials are the best bet, but they are very hard to find. I was missing front and rear for the left side and eventually some friends in the Netherlands found some for me (many thanks Selma and Rob). I had purchased a set of plastic base cards to avoid the damp/distortion which happens to nearly all door cards on old cars. These were expensive and a little heavier than traditional mill board, but they were fairly accurately cut and saved me a lot of time. I decided to attatch the rests in a completely different way to the factory. I cut sections out of aluminium sheet and attached the pressed cardboard 'blips' using a combination of rivets and screws/speed clips. All the holes had to be very accurately drilled. next, the molded foam rubber was glued on, and I also glued some self-adhesive 5mm closed cell foam sheet (s/a side up) to the lower part of the blip and the aluminium base. The same foam sheet was also glued to the rest of the door card, leaving a small gap around the area of the blip/aluminium for the cloth covering the main card to tuck into. The screws would eventually be used to attach the top of the arm rest assembly to the plastic door card from the back . . . . | ||