|  | |||

|  | |||

| ||||

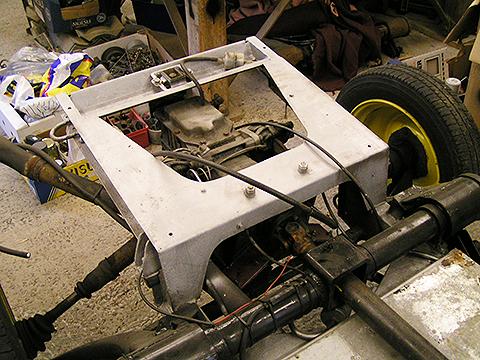

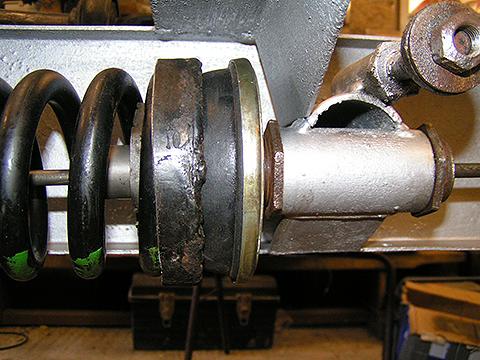

Dyane 4x4 Chassis details Top left picture shows the rear of the chassis where it kicks up over the rear diff and drive shafts. Unlike most of the Louis Barbour 4x4s, the rear panel on the body (where the lights are) is not cut away (so looks almost standard at the back), but this means the chassis stops short, and the rear bumber is carried on a specially fabricated bracket which bolts on to the underside of the raised rear legs. (Top right) - the 50% uprated springs were originally encased, but during this rebuild I cut the end plates off the cans, and re-mounted the springs on larger (Ami 8) buffers (or 'doughnuts') to support them better. These doughnuts have a slightly larger hole in the centre; so I made a sheet metal sleeve to take up the slack. With normal 2CV doughnuts the open springs can 'sag' when not under compression (ie. when you take off . . .). Lower photos show rear and front 'knife edges'. The adjustable rods which tension to compress the springs (?) rock on semi-triangular pins (rather than pivoting which could cause friction). Louis Barbour supplied pins with special brackets for the back (stops them rotating). Plenty of grease at all times is vital. I used special long threaded pivot 'eyes' (designed for lowered kit cars) on the front, to compensate for the lack of safe thread caused by the stiffer springs. . | ||||