| ||

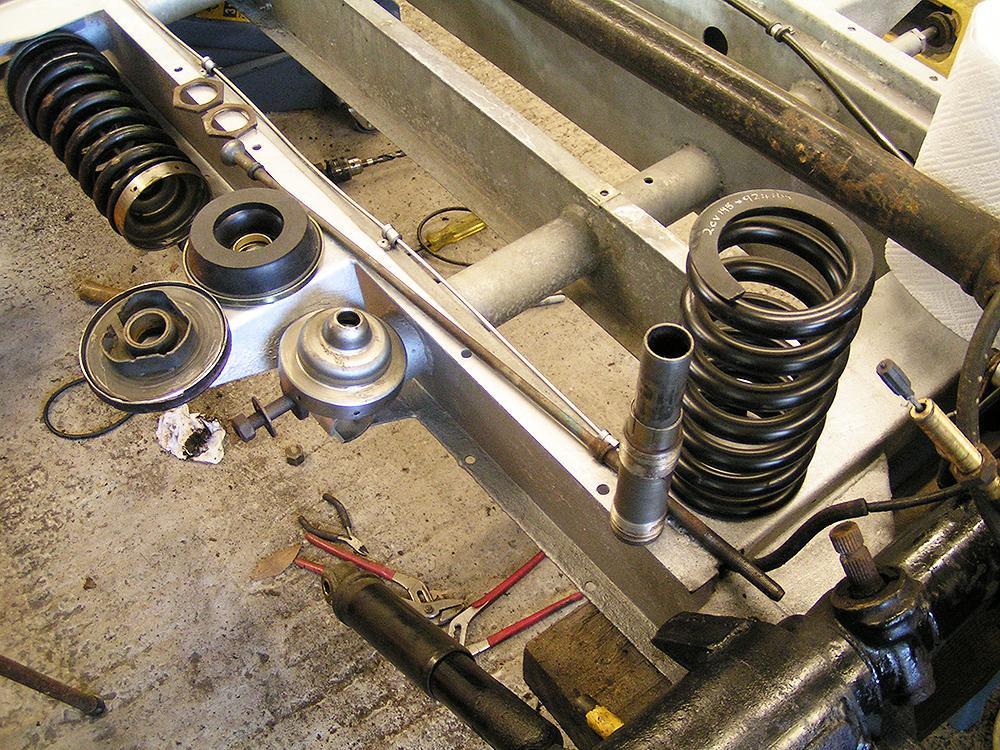

Dyane 4x4 springs Because of the extra weight of the rear differential, 50% uprated REAR springs were fitted as part of the original conversion, but the original (fairly worn out) FRONT springs remained. However, the whole chassis is considerably heavier (and much stiffer) than standard, and it was impossible to adjust the front high enough to get a little extra ground clearance without the springs simply squashing flat. I asked Louis Barbour supply me with a pair of uprated front springs, and the car now has good ground clearance and the roll stiffness is considerably improved (but it's still much more comfortable than most modern cars). Here you can see the end plates I cut off the original spring cans, and the new Ami 8 'doughnuts' used to better support the open springs. I spent much time cleaning all the gunk off the end plates and preparing all the other parts. Also visible is the packing sleeve on the front threaded carrier tube, prior to bolting it into the chassis. Most of the Barbour 4x4 2CVs have fixed spring pans (welded to the chassis), but because our Dyane was always intended primarily for road use it was built originally with a more 'standard' setup. Both chassis plates are removed at this point, revealing the excellent condition inside (heavily galvanised). The brake line (and fuel line from the internal tank) can be seen running inside the chassis to the engine bay (very well protected). All new stainless bolts were used to re-attach the galvanised plates. . | ||